68kMLA Classic Interface

This is a version of the 68kMLA forums for viewing on your favorite old mac. Visitors on modern platforms may prefer the main site.

| Click here to select a new forum. | |

| Lithium Polymer battery for PB100 (and maybe portable) | |

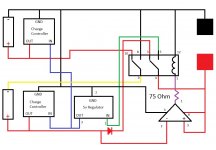

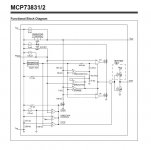

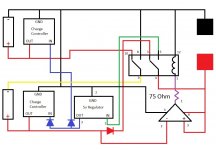

| Posted by: 360alaska on 2016-02-19 08:22:42 Hello all, I'm trying to design a battery to replace the original lead acid with Lithium polymer. with inspiration from this article: https://learn.adafruit.com/multi-cell-lipo-charging/fast-multi-cell-charger Here is my design so far:  For the 5v regulator we'll use a self contained switching unit: http://www.newark.com/tracopower/tsr-1-2450/dc-dc-converter-non-iso-pol-1/dp/08R5932 The charge controller circuit will be the same as this: https://cdn.sparkfun.com/datasheets/Prototyping/SparkFun_Lipo_Charger_Basic-microUSB_v10.pdf Basically, this guy will connect the batteries through a relay for operation and split them for individual charging. A 1n4001 diode prevents charging of the batteries in series and also drops the voltage to a level that won't hurt the Powerbook. For safety purposes, each Lipo battery will be equipped with a Battery management board in case of a failure and to prevent over-discharging. A comparator circuit will switch the batteries into charge mode whenever the combined voltage of the batteries is less than that of a plugged in power adapter(around 40-70% charge):  | |

| Posted by: Paralel on 2016-02-19 09:19:37 Unless you are a true master of battery design, LiPo is extremely dangerous. Just the smallest bugs in the regulation system can lead to an explosion that leaves a hole in someone. Maybe I just have bad experience with them, but I had a friend, masters in electical engineering, trying to do something similar with LiPo batteries. For some reason he didn't anticipate, his regulatory circuity went into a race condition and locked up. As a result the cells experienced a thermal run away, it detonated and literally left what looked like a mortar hole in the floor of his basement. I've never wanted to go near them since. I think this is the reason we haven't seen LiPo cells for old Mac laptops before, without the LB knowing what is there, all the safety has to be in the battery, and one mistake, boom. | |

| Posted by: 360alaska on 2016-02-19 09:28:03 did he use a protection circuit? http://cdn.sparkfun.com/datasheets/Prototyping/BatteryProtection.pdf I should add that this is the battery I will qualify my design with: https://www.sparkfun.com/products/8483 | |

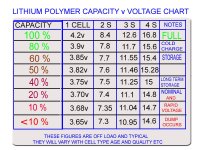

| Posted by: techknight on 2016-02-19 15:25:06 you should use cells with the protection circuits built in, like ones used in older cellphones and MP3 players. Oh, and since the discharge voltage/curve is different than an SLA, the battery meter on the machine will most likely not be accurate, or even work properly at all. but honestly in my opinion, DO IT! because thats the kind of insane strange shit that I do on a day to day basis. | |

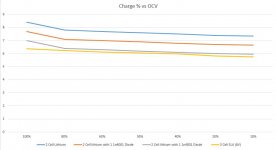

| Posted by: 360alaska on 2016-02-19 16:23:16 Thanks for the encouragement! I'll keep you updated. Maybe I can use a second diode to keep the voltage closer to Lead Acid. A little graph I made:  | |

| Posted by: rsolberg on 2016-02-20 10:10:35 Great work! Have you considered LiFePO4 cells as an alternative? They tend to be more stable and have more forgiving charging characteristics. I've seen implementations that use LiFePO4 packs as drop in replacements for SLAs, even utilizing the original charging circuitry. | |

| Posted by: 360alaska on 2016-02-20 12:06:09 I'm not ruling it out at this point... | |

| Posted by: techknight on 2016-02-20 16:30:59 I am going to use the lithium iron phosphate (LiFEPo4) in our solar applications, so it might be a good alternative. | |

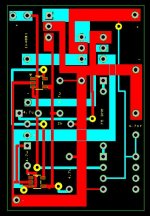

| Posted by: 360alaska on 2016-02-20 18:44:59 I made a board for this project, when I get it I'll give er a try:  | |

| Posted by: 360alaska on 2016-03-20 13:17:12 Well, looks like my design is full of holes 🙂 I'm really not sure what happened, I'm gonna have to shoot OSHpark an email.   | |

| Posted by: techknight on 2016-03-20 14:45:53 yea... somethings wrong there. Personally, I would use iTead, or Mier. | |

| Posted by: gsteemso on 2016-03-20 17:11:46 About 15 years ago, I drove a fellow home (my job at the time was "professional designated driver") whose company had developed a method of building lead-acid batteries which, though having completely traditional chemical composition, had greatly improved energy density by reason of using "foamed" (extremely porous) lead electrodes, which naturally had vastly greater surface area than the traditional simple lead plates… or so he proudly claimed, at least. It would be interesting to find out if they ever succeeded in commercializing that. You could in theory run your Portable for twice as long with minimal or no alterations. | |

| Posted by: flecom on 2016-03-20 17:17:19 looks like a problem in your drill file | |

| Posted by: 360alaska on 2016-03-20 22:37:17 Yeah haha, im looking into it... | |

Posted by: Paralel on 2016-03-20 23:50:27Well,What the heck was that supposed to be? Swiss cheese? About 15 years ago, I drove a fellow home (my job at the time was "professional designated driver") whose company had developed a method of building lead-acid batteries which, though having completely traditional chemical composition, had greatly improved energy density by reason of using "foamed" (extremely porous) lead electrodes, which naturally had vastly greater surface area than the traditional simple lead plates… or so he proudly claimed, at least. It would be interesting to find out if they ever succeeded in commercializing that. You could in theory run your Portable for twice as long with minimal or no alterations.They tried that theory with Li-Ion, didn't work out, explosivity, etc... | |

Posted by: flecom on 2016-03-23 23:30:24Yeah haha, im looking into it...did you send them as gerber files? use gerbv to look at your DRD file I check all my individual layers before sending them off, have caught a few errors like that that are not imminently obvious ex mirroring the wrong layer or overlapping value/placement silk screening or something | |

| Posted by: 360alaska on 2016-03-24 09:29:36 I did send gerber files, I'm going to remake them and hopefully it goes better this time... | |

| Posted by: flecom on 2016-03-25 12:47:58 before sending them look at them with gerbv... check the DRD file and make sure you don't have massive holes again 🙂 | |

| Posted by: 360alaska on 2016-04-19 16:04:32 Well, I gave it a try with bad results, once I had it assembled I checked the output terminals and discovered that I only had 2.8v. I did a little probing and I think that the charge controllers allow voltage to pass in reverse from output to input causing one battery to be connected straight to the output terminals and causing the other to be shorted and go into protection mode.  So, I've added some diodes to mitigated the problem:  | |

| 1 > |